Wheelchair Handrims

The handrims, sometimes known as pushrims, of the wheelchair are the part the wheelchair user grips to propel the wheelchair. Handrims are attached to the wheelchair wheel by a set of bolts and can be removed to narrow the wheelchair for people who don't self-propel their wheelchair. There are several types and and styles of wheelchair hand rim and each have their own benefits and drawbacks.

Chrome Handrims

Chrome handrims are pretty rare these days but still available on some models. Aluminum, the preferred wheelchair material these days, cannot be chromed and not many manufacturers offer steel chromed handrims because of the weight. You'll still find chrome on institutional wheelchairs but that's about the only place.

Aluminum Anodized Handrims

Aluminum handrims are by far the most common handrims and are usually standard equipment on many wheelchair models. Because aluminum is a dirty material and will continually shed a fine black dust the manufacturers will have their aluminum handrims anodized to seal them and prevent the oxidization that causes the black dust.

Composite Handrims

Composite handrims are plastic like handrims that are often found on the lowest priced wheelchairs. There isn't really anything wrong with this type of handrim except the back side facing the wheel is often open and I've had some customers complain that they didn't like them for that reason.

Vinyl Coated Handrims

Vinyl coated handrims are usually aluminum with a plastic coating applied to the surface to provide a surface that because of friction is much easier to grip than a smooth chrome, aluminum or composite surface. They tend to be a little larger in diameter as well adding to the ease of gripping.

There are a couple of negatives with plastic coated handrims. One is the vinyl can get chipped off over time creating a rough surface and exposing the non-anodized aluminum rim underneath. The second negative is, when a wheelchair user is rolling down a hill or ramp they will usually let the handrim slip along inside their closed hand and apply pressure to the rim to control their speed. Because the vinyl coated handrims use friction to improve the grip of the user a lot of heat is generated when the wheelchair speed is controlled this way.

Foam Covered Handrims

Foam covered handrims are covered with a thick soft foam that looks similar to pipe insulation. Because the foam is soft and has a bit of friction some users find them quite easy to grip and propel their wheelchair. Over time this foam will chip off like the vinyl coated handrims but because the foam is soft the surface of the handrim is not as rough.

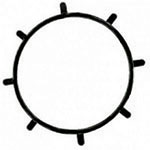

Projection Handrims

Projection handrims employ about a dozen short (¾" to 2") nubs, bumps or knobs that extend vertically from the wheelchair handrims. Projection handrims are quite rare and intended for users who are unable to grip the handrim at all. The idea is they will use the palms of their hands to push on the projections and propel the wheelchair that way. Of course some care must be taken when trying to control their speed as in the previous example but for those who need projection handrims they are often the only thing that will work.

Oblique Projection Handrims

Oblique projection handrims are the same idea as projection handrims but the projections are longer (1" to 3") and they project at about 45° outward from the handrim instead of vertically.

Natural Fit Handrims

The Natural-Fit is a uniquely designed wheelchair handrim that maximizes the fit between the user’s hand and the rim. The Natural-Fit comes in two pieces: The contoured thumb area and the oval component. It is the combination of these two components that gives the Natural-Fit its unique ability to provide a superior gripping surface, a place to rest your thumb, and dual surfaces for propulsion and braking. Note: This is an aftermarket item and not available from the wheelchair manufacturers.

Online Vendors

Online Vendors  US Online Vendors

US Online Vendors